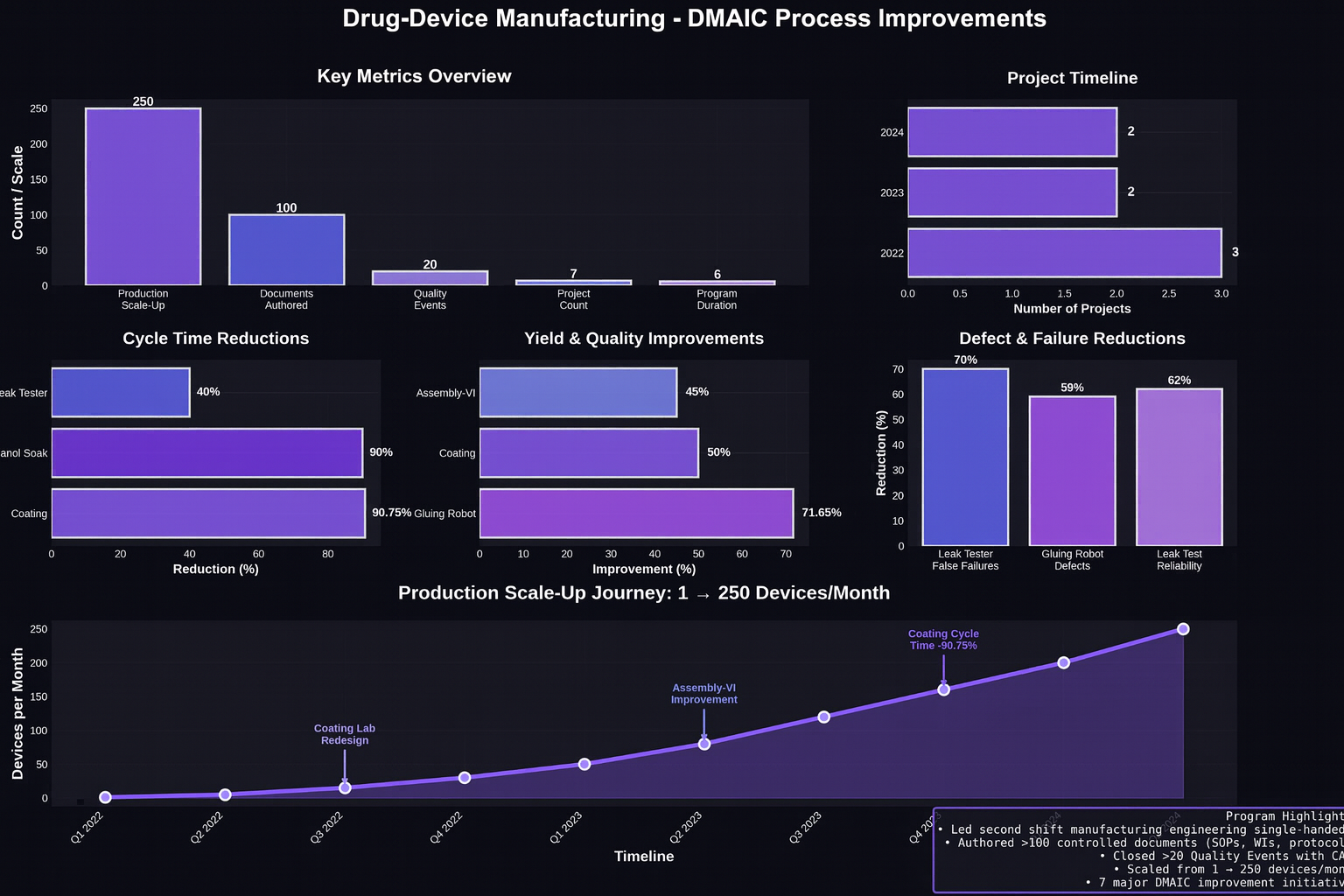

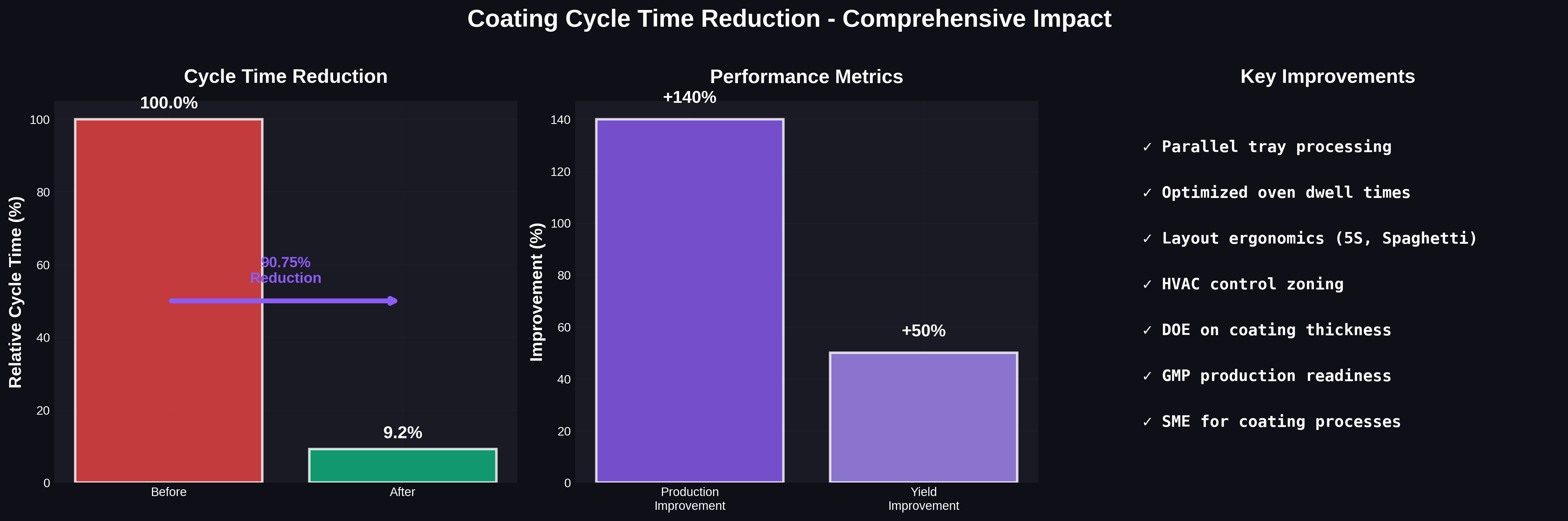

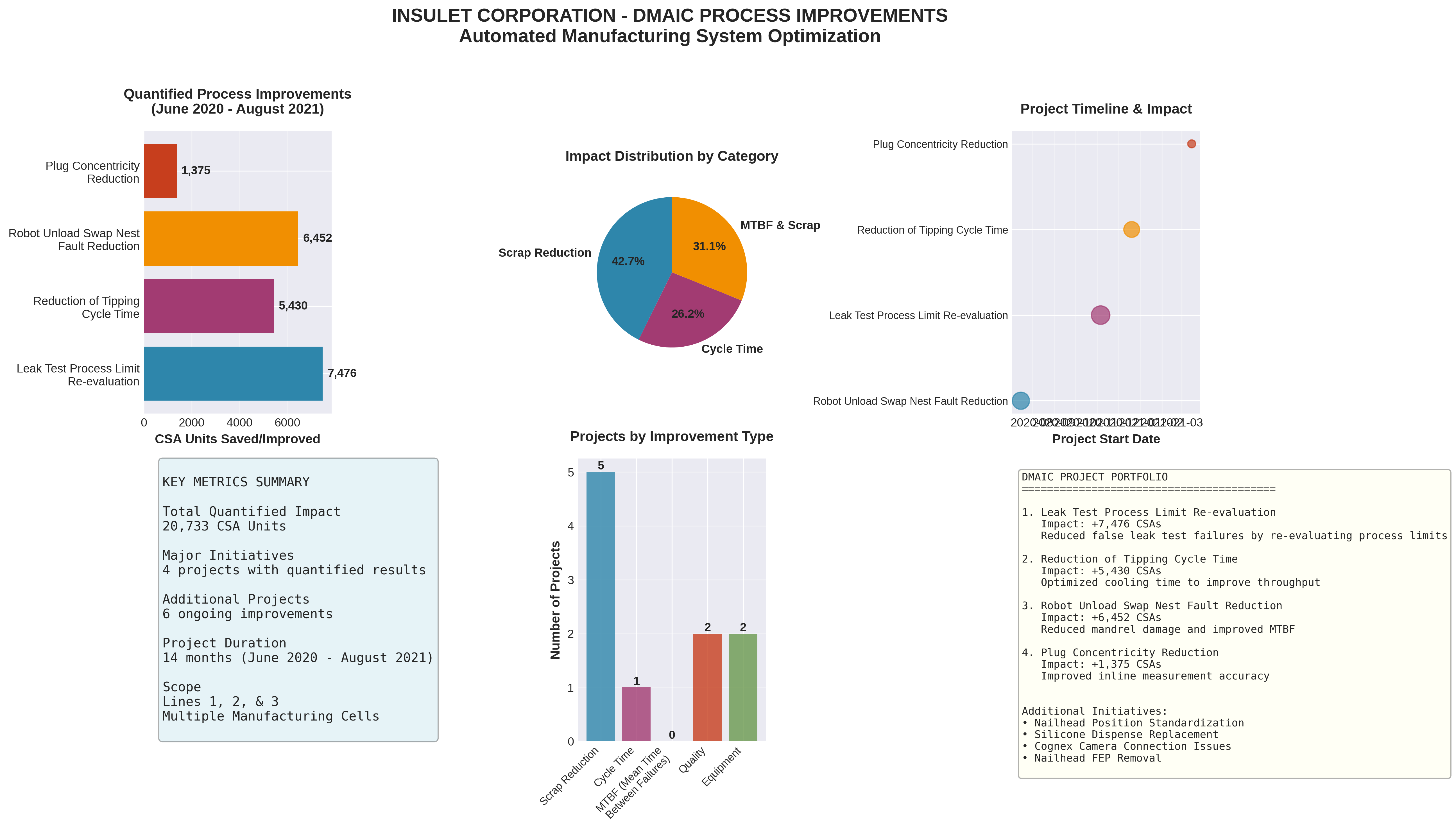

DMAIC Process Improvements

High Volume Fully Automated Manufacturing System - Insulet Corporation (100k+ parts/day)

Manufacturing Engineer | June 2020 - August 2021

Major Project Initiatives

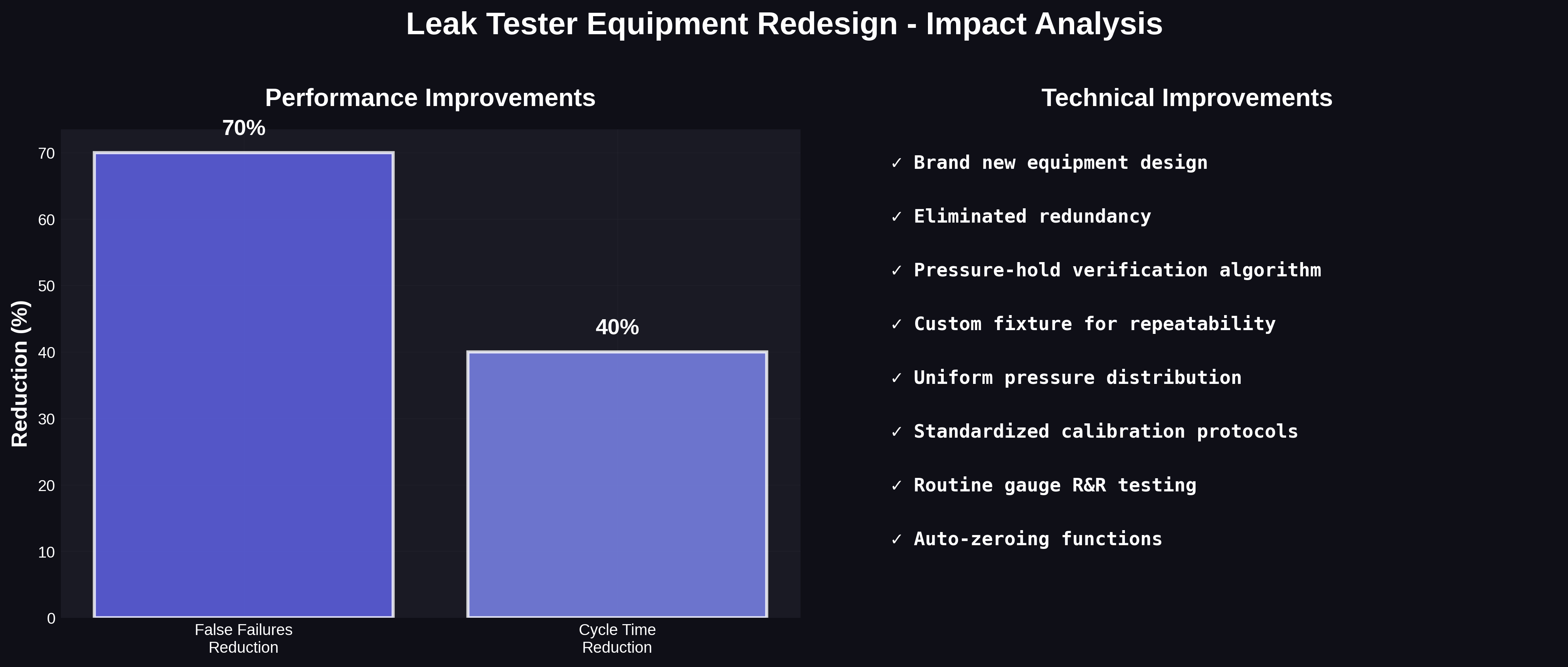

1. Leak Test Process Limit Re-evaluation

+7,476 Parts Per DayDuration: November 2020 - June 2021

Scope: Lines 1, 2, & 3 - All Station 45MM leak testers

Problem: Most in-line leak test failures were false positives - system failures at tester seals rather than actual part defects.

Solution: Conducted comprehensive data analysis, re-evaluated process limits based on actual failure modes.

Results: Significantly reduced false reject scrap and improved overall throughput.

2. Reduction of Tipping Cycle Time

+5,430 Parts Per DayDuration: December 2020 - June 2021

Problem: Production rate below 6 PPM target. Cooling time on tipping station identified as bottleneck.

Results: Saved 1 second per part cycle time, increased throughput across all lines.

3. Robot Unload Swap Nest Fault Reduction

+6,452 Parts Per DayDuration: July 2020 - June 2021

Results: Increased MTBF (Mean Time Between Failures) by 3,158 units, reduced scrap by 3,294 units.

4. Plug Concentricity Reduction

+1,375 Parts Per DayDuration: March 2021 - June 2021

Results: Reduced false rejects, improved throughput, established offline validation protocol.

Technical Skills & Methodologies

Additional Process Improvement Initiatives

- Nailhead Position Standardization - Reduced Cell 80 scrap through standardized positioning

- Silicone Dispense Replacement - Eliminated air bubbles, reduced nailhead tears and NCMRs

- Cognex Camera Connection Issues - Reduced camera replacement frequency and fault downtime

- Nailhead FEP Removal - Improved MTBF of FEP removal process

- Needle Bender Scrap & Fault Improvement - Optimized inspections and reduced false failures

- NH and Tipping Inspection Scrap Reduction - Enhanced vision systems to reduce false rejects